Dyeing

After knitting, grey fabric is inspected using a grey fabric inspection machine. In the batch department this grey fabric is collected in order to dye a particular shade of color.

During the batch making we give priorities to weight the fabric correctly and accurately for creating a correct recipe and avoid dye and chemical wastage along with mismatched shades.

Dyeing Process

BATCHING → PRE-TREATMENT → DYEING →SAMPLE KNITTING →

SAMPLE CHECK → HYDRO EXTRACTION → DRYING → QUALITY CONTROL

PROCESS CONTROL

“Right First time” is our prime objective and to achieve this we have process control department which makes sure that all the parameters are strictly being followed to get best quality right first time. Sadma dyeing has independent function of process control with experienced professional, who continuously monitor and control all processes & parameters according to requirements. With the help of our experienced professional Sadma Dyeing reprocess ratio is only 2%.

GREY FABRIC STORE

Grey fabric is inspected using a grey fabric inspection machine after it is manufactured

on a knitting machine. In the textile business, it is done in the batch department.

Grey fabric from grey fabric store is collected in order to dye a particular shade of color.

During the batch making we give priorities weight the fabric correctly and accurately

for creating a correct recipe and avoid dye and chemical wastage along with shade

mismatched shades.

PLANNING & EXECUTION

- Preparing a batch card in which all the parameters of the required fabric is noted

- Receiving required quantity of body fabric according to the machine capacity from the fabric store

- Taking required quantity of collar/cuff fabric

- Sending the grey fabric to the dyeing section by trolley with the respective batch card

- Make the priority as per dyeing plan

- Take one specific Batch card.

- Read the Batch Card for own understanding

- Take required quantity of body fabric from warehouse

- Make required no. of Rope maintaining equal length

- Take collar/cuff as per size, keep the total weight

- Distribute the collar/cuff or rib in each rope equally to ensure equal length.

- Stitch the fabric

- Write down the weight against roll no. in the back side of the Batch Card

- Write the total weight in Batch Card

- Put signature & date

- Fill up the production report form

- Send for the Production

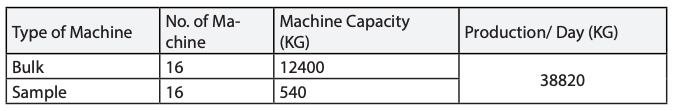

MACHINE POSITION

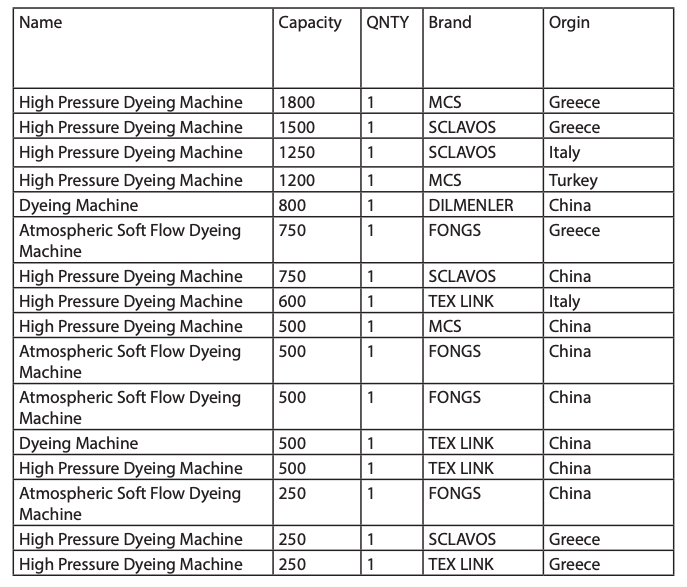

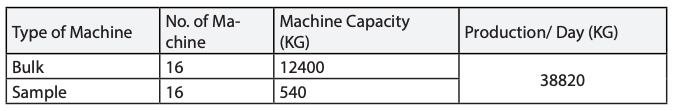

— BULK MACHINE

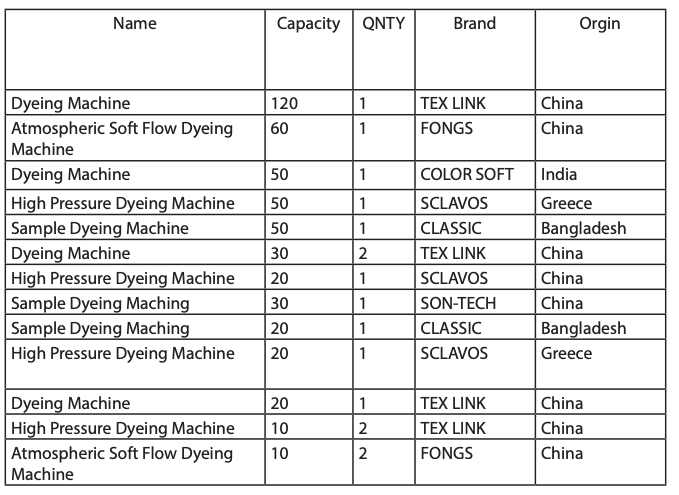

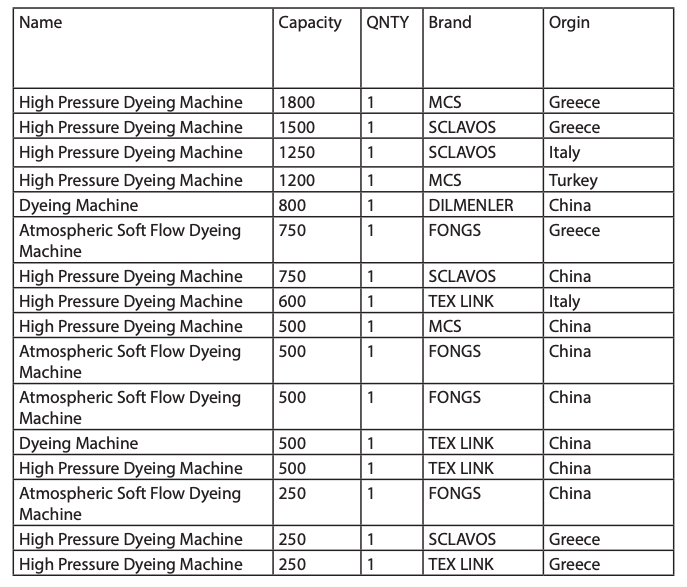

— SAMPLE MACHINE

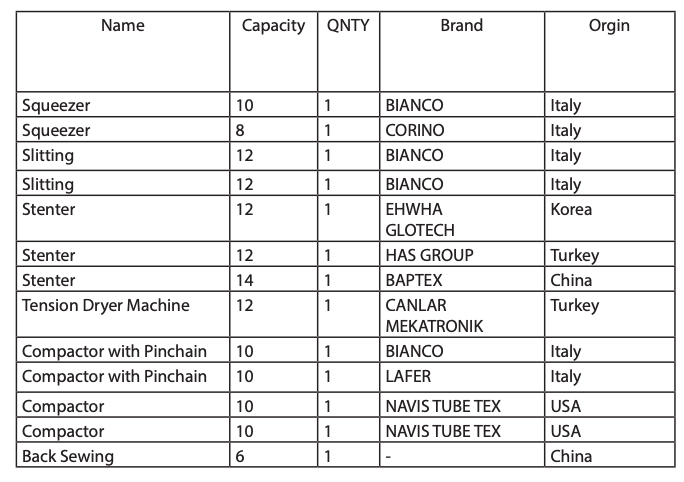

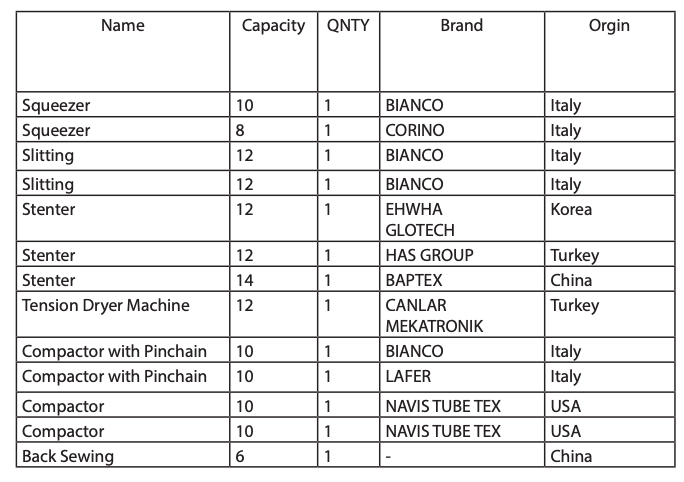

— FINISHING MACHINE