Knitting

Knitting is a method by which yarn is manipulated to create a textile or fabric. It is used in many types of garments. Knitting may be done by hand or by machine. Knitting is considered to be the second most frequently used method of fabric construction after weaving. In this process yarns are interloped to make thick yet flexible and elastic fabric. The knitting operation creates multiple active stiches at one time in the knitting machine. These stiches are done by the needle of the machine. The fabric consisting many consecutive rows of intermeshing of loops. As the progress of one loop, another loop is created simultaneously. In the knitting, different types of yarns, needles and loops or stich types may be used to get the proper color, texture, looks, elasticity and water resistant fabric. Knit fabric is considered in weight unit KG. After knitting the fabric, send to the dyeing unit for necessary dyeing. The knitting technology has been playing a very vital role in our life style since 1000 B.C. It not only produces fabrics and shaped garments for apparel and household purposes but also for various technical end applications color the fabric and rest processes.

Knitting Process

SAMPLE FABRIC DESIGN ANALYSIS → MACHINE SELECTION →

SETTING THE MACHINE FOR THE SPECIFIC DESIGN →SAMPLE KNITTING →

SAMPLE APPROVAL → BULK PRODUCTION → GREY FABRIC INSPECTION

We Produce

Machine Position

2. Single Jersey With Fleece

4. Auto Stripe Single Jersey Machine

YARN RECEIVING, STORING & DISTRIBUTING

Our system design consists of four parts. The first part saves the buyers information and all the order information that are needed. The second part contains the yarn receiving section in which the employees get all the yarn and they are prepared to do the work for the next level. The third part contains the works that are done in knitting section where the employees start the knitting process different parts. All information is stored in a database. At last, the system will generate the whole report of the works that are done in previous sections.

PRODUCTION PLANNING, EXECUTION, AND TRACABILITY MAINTAINING

Production planning and control (PPC) is essential for our company’s success. To get maximum output of the export order, production planning and control (PPC) needs to create positive relations with other departments.

QUALITY

The quality control department’s job is to ensure that the material in process and at different stages of production are of consistently high quality. After collecting fabric rolls from multiple machines, quality inspectors must inspect these fabrics thoroughly to ensure the required quality before dyeing.

MAINTENANCE

The maintenance department is operated by professionals in the maintenance department to keep the continuous production system running and the machinery in good operating order. One of the most crucial elements of the manufacturing is the maintenance department. The main responsibility of the maintenance department is to keep the machines and other manufacturing equipment in good operating order.

Fabric Store & Delivery

Sadma Fashion Wear Ltd.’s fabric store’s database is integrated with an interactive front end, which will be user friendly and will allow the users of the software to easily carry out all their business functions. Overall reports, production controls can be generated using this software.

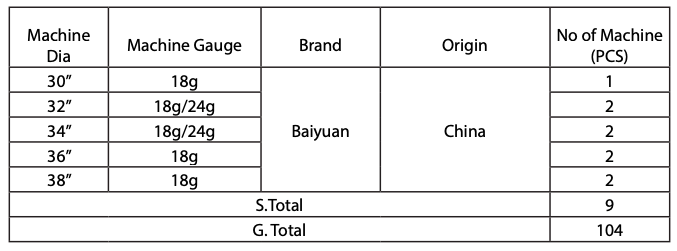

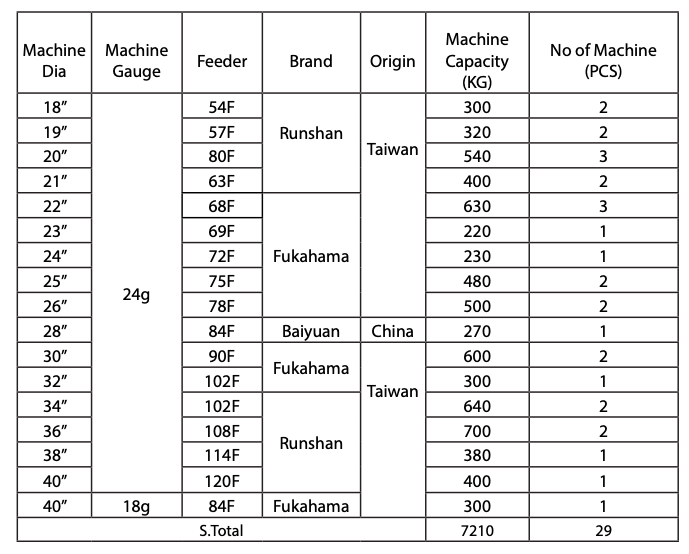

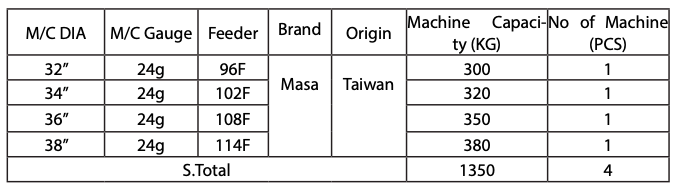

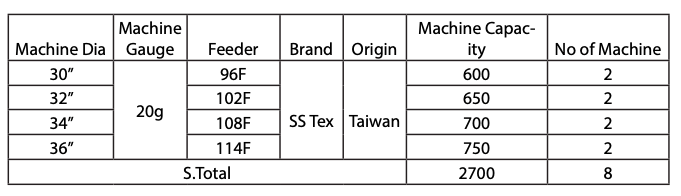

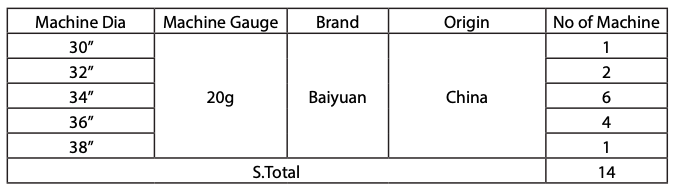

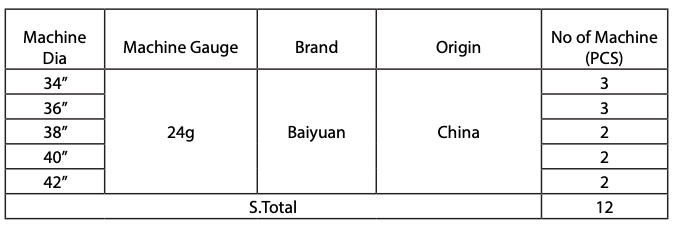

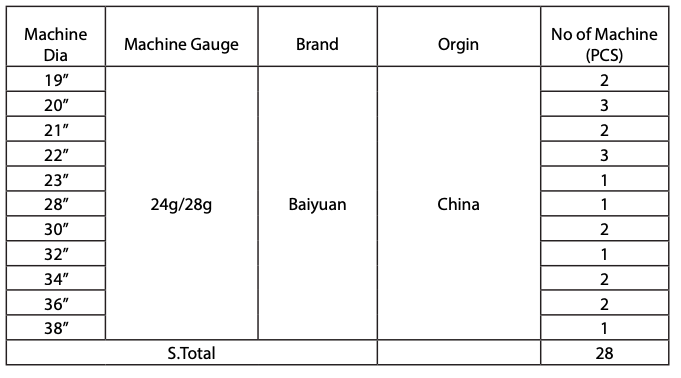

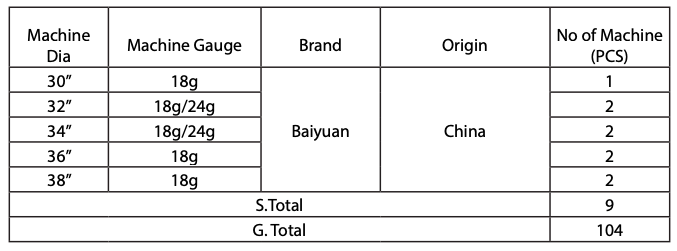

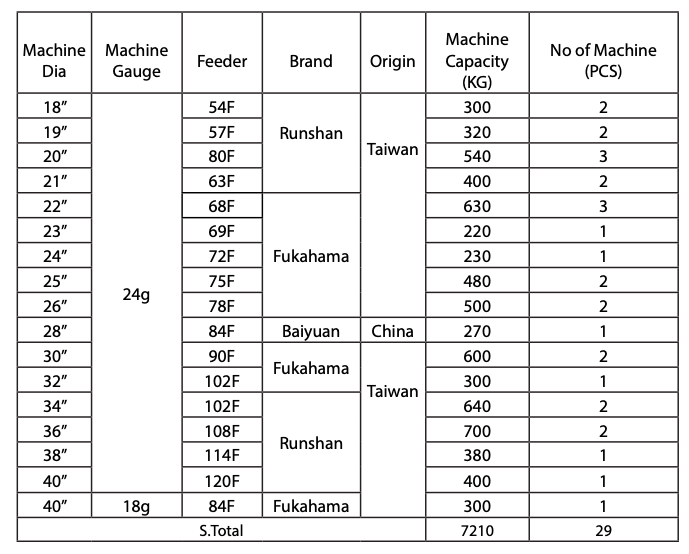

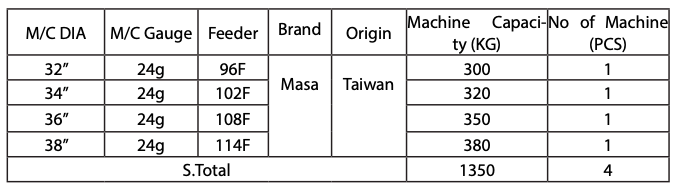

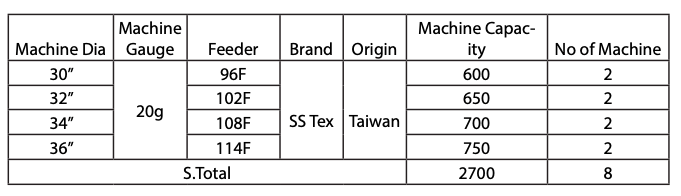

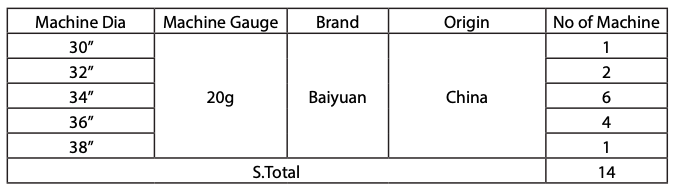

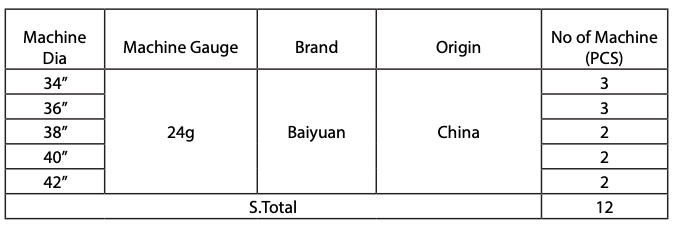

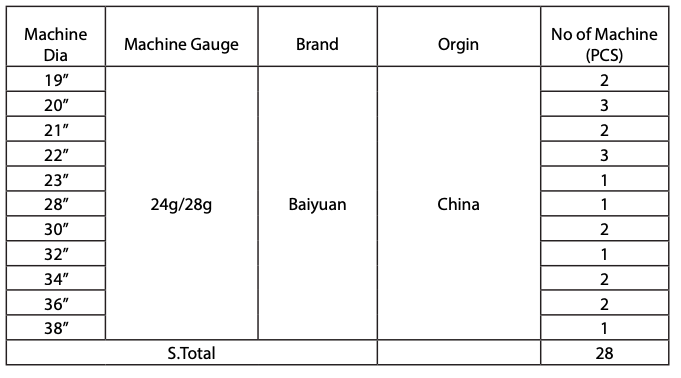

MACHINE POSITION

— TUBULAR SINGLE JERSEY M/C

— Open Width Single Jersey M/C (WITH FULL FEEDER LYCRA ATTACHMENT)

— FLEECE M/C (FULL FEEDER LYCRA ATTACHMENT)

— FLEECE

— OPEN WIDTH MACHINE

— TUBE MACHINE

— RIB INTERLOCK